Thermal Imaging

Introduction

As an integral part of our manufacturing process for polished and coated finished optics, we proudly offer generated blanks with precise tolerances tailored for thermal imaging applications. The primary materials utilized in the majority of our lenses, spanning various applications, are ZnSe and ZnS. These lenses are meticulously crafted to meet the highest industry standards, underpinned by state-of-the-art metrology techniques.

With our advanced manufacturing capabilities, we can accommodate diameters ranging from 15mm to 150mm, ensuring versatility and flexibility to meet diverse customer needs. Whether for thermal imaging or other optical applications, you can rely on ULO Optics to deliver precision-engineered optics of the utmost quality and reliability.

ZnSe Generated Blanks

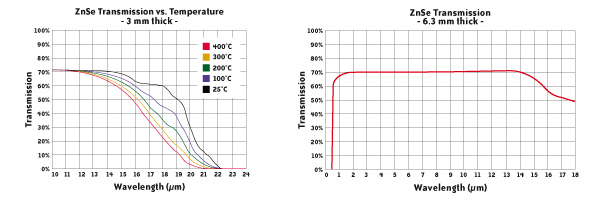

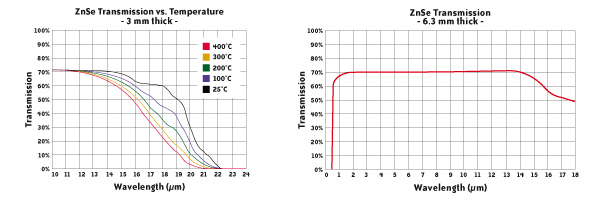

ZnSe stands out as the material of choice for a wide array of optics, thanks to its exceptional visible transmission properties and low absorption at infrared wavelengths. Particularly in high-power applications, meticulous attention to detail is crucial to ensuring optimal performance. This includes careful control of the internal defect structure and bulk absorption, along with the utilization of minimum-damage polishing techniques and top-tier coatings.

At ULO Optics, we prioritize quality assurance at every step of the manufacturing process. To guarantee the reliability and performance of our ZnSe components, we employ CO2 laser calorimetry to meticulously assess material absorption in atmospheric environments. This rigorous testing procedure is conducted on each and every component, and we are equipped to provide comprehensive testing certification upon request. With our commitment to precision and excellence, you can trust ULO Optics to deliver optics of the highest caliber for your specific application needs

Zinc Sulfide Generated Blanks

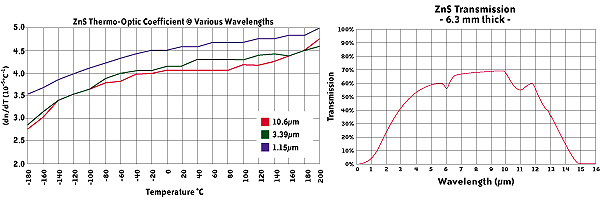

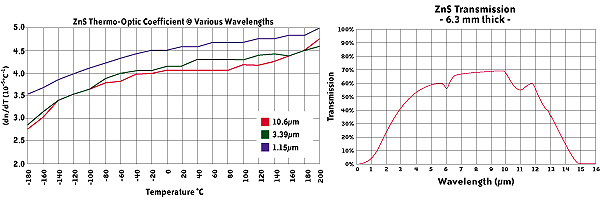

Our Zinc Sulphide is cultivated through a meticulous chemical vapor deposition process, resulting in a material renowned for its exceptional hardness and fracture strength. This remarkable durability makes Zinc Sulphide an ideal choice for applications in harsh environments and military settings.

Notably, Zinc Sulphide’s resistance to high-speed dust abrasion and rain erosion further enhances its suitability for external infrared (IR) windows on aircraft. These windows play a critical role in maintaining visibility and functionality in challenging conditions, ensuring optimal performance even in adverse weather conditions.

At ULO Optics, we take pride in offering Zinc Sulphide solutions that exceed industry standards, providing reliability and durability in the most demanding environments. Whether for military applications or other high-stakes scenarios, our Zinc Sulphide products deliver unmatched performance and peace of mind.

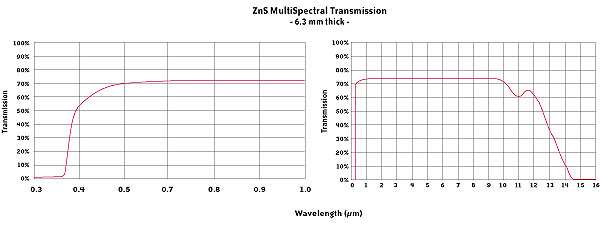

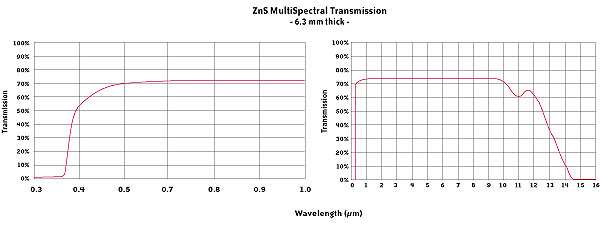

MultiSpectral Zinc Sulfide

Multispectral Zinc Sulfide undergoes a meticulous hot isostatic press treatment process, designed to eliminate any defects present within its crystalline lattice. This specialized treatment ensures the material’s integrity and enhances its optical properties.

Known for its exceptional performance across a broad spectrum of wavelengths, spanning from 0.4 to 12 microns, multispectral Zinc Sulfide stands out for its remarkable attributes. With high transmission capabilities and minimal scatter, it offers unparalleled clarity and efficiency in various optical applications.

ULO Optics offers multispectral Zinc Sulfide customized to exacting specifications, ensuring that each product meets the stringent requirements of our customers. From precision optics to cutting-edge technologies, our commitment to delivering excellence remains unwavering, making us the trusted choice for all your optical needs.

Unveiling the World Through Thermal Imaging Optics

Thermal imaging optics, once the realm of science fiction, have become indispensable tools across a myriad of industries. From military and law enforcement to industrial maintenance and wildlife conservation, ULO’s thermal imaging optics provide a unique perspective on the world by capturing infrared radiation emitted by objects and converting it into visible images.

Military Applications

In military operations, our thermal imaging optics offer a crucial advantage by allowing soldiers to detect heat signatures, even in complete darkness or through dense foliage. This capability enables enhanced situational awareness, target acquisition, and surveillance, empowering troops to operate with increased efficiency and effectiveness on the battlefield.

Law Enforcement and Search and Rescue

In law enforcement and search and rescue missions, thermal imaging optics play a vital role in locating missing persons, detecting hidden threats, and conducting covert operations. By revealing heat signatures, these optics enable law enforcement officers and rescue teams to navigate challenging environments and swiftly respond to emergencies, ultimately saving lives.

Industrial Maintenance

In industrial settings, thermal imaging optics are indispensable for detecting overheating components, identifying energy inefficiencies, and troubleshooting mechanical systems. By visualizing temperature variations, these optics enable maintenance professionals to proactively address issues, minimize downtime, and optimize operational efficiency.

Advancements and Innovation

Recent advancements in thermal imaging optics have led to smaller, lighter, and more affordable devices with enhanced performance and capabilities. From handheld thermal cameras to unmanned aerial vehicles equipped with thermal sensors, the possibilities for utilizing thermal imaging optics continue to expand across various industries and applications.

Thermal imaging optics have revolutionized how we perceive and interact with the world around us. With their ability to reveal the invisible and unveil hidden details, our optics have become invaluable tools for enhancing safety, efficiency, and productivity across diverse sectors, ushering in a new era of exploration and discovery!