Reflectors

Optimized & Industry-ready Solutions

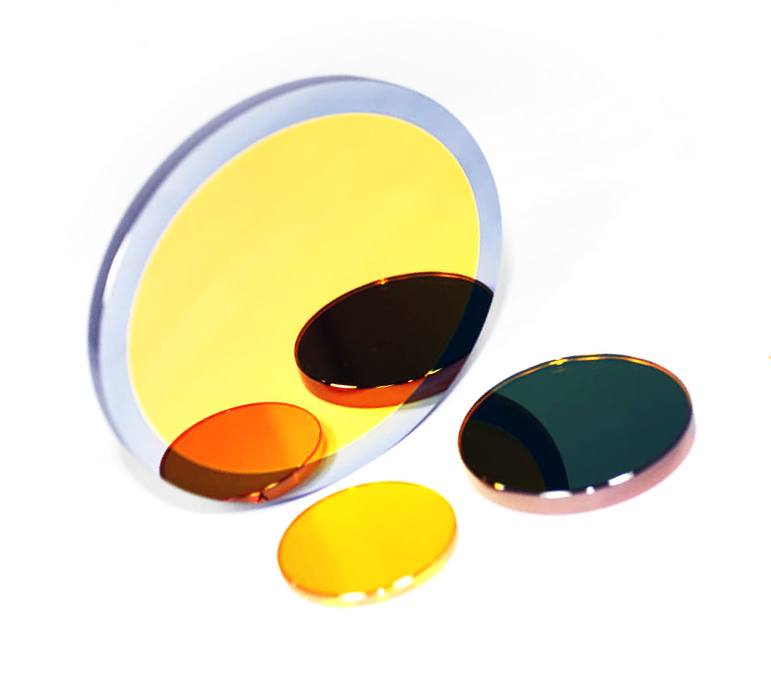

Partial Reflectors

Partial reflectors are used in laser cavities or outside the laser to split the beam. In the former case, the coatings will specified for normal incidence and for the latter, the coating is usually for use at 45 degrees angle of incidence. When used at non-normal incidence, the polarisation also needs to be considered, S , P or R (same as AV). The most common beam splitter coating is a 50% for splitting the beam into two equal power beams.

The polarization needs to be considered when specifying a beamsplitter otherwise the reflected and transmitted beams will not have the correct power. ULO Optics has a special ‘polarization insensitive’ coating which eliminates this problem for the 50:50 case, reflecting 50% of both S and P polarization. Incident circularly-polarized radiation is split equally into two circularly polarized beams.

Polarization Insensitive Beamsplitters

Beamsplitters allow a single beam to be split into two beams of differing power. The most popular power split is 50:50 at a 45° incidence angle, but other ratios are also available. The polarization needs to be considered when specifying a beamsplitter otherwise the reflected and transmitted beams will not have the correct power.

ULO Optics has a special ‘polarization insensitive’ coating which eliminates this problem for the 50:50 case, reflecting 50% of both S and P polarization. Incident circularly-polarized radiation is split equally into two circularly polarized beams. Germanium is used as one of the coating layers, so the coating is visually opaque, and the beamsplitter cannot be used to split visible pointing-beams. Due to the relatively high level of absorption in the coating, incident intensity levels should not exceed 500 W/cm2 in order to avoid thermal-lensing effects.

- Split ratio 50:50 +/- 1%

- 45 degree incidence angle

- Other reflectances and angles of incidence are possible

Flat & Curved Partial Reflectors

ULO Optics’ flat and curved partial reflectors are used as output couplers in CO2 laser cavities. Many of our partial reflectors are available with reflectance values for use at normal incidence between 1% and 99.6%.

A full range of polarisation specific partial reflectors are available for use at 45 degrees to split the beam are also available, see beam splitters.

- Many different reflectance values available

- Flat or curved partial reflectors available

- OEM equivalents for your cavity available

Specifications

| Part Number | Field Size | Focal Length | Spot Diameter (s.d.)* |

| ZSD-15-75 | 50 mm | 75 mm | 118 (25) micron |

| ZSD-15-100 | 70 mm | 100 mm | 139 (22) micron |

| ZSD-15-150 | 105 mm | 150 mm | 171 (0) |

| ZSD-15-200 | 140 mm | 200 mm | 225 (0) micron |

| ZSD-15-250 | 175 mm | 250 mm | 282 (0) micron |

| ZSD-15-300 | 210 mm | 300 mm | 338 (0) micron |

| ZST-15-75 | 50 mm | 75 mm | 89 (4) micron |

| ZST-15-100 | 70 mm | 100 mm | 113 (1) micron |

s.d.* = Standard deviation

Spot diameter is determined from optical computation and are not measured values from marking or engraving. The width of an engraved line is affected by laser power, material, scan speed, etc and is normally less than the values listed here.

Please note that this page is only a representation of our most commonly used replacement f-Theta multi-element lenses and is not our entire product line. If there is an item not listed or you have questions, please feel free to contact us and we will be more than happy to assist you.

Curved Partial Reflectors

The following curved partial reflectors are available, others are available upon request.

| Part No | Material | Diameter | ET | Coating |

| 5.9ZPC0010 | ZnSe | 15mm | 3mm | AR/85% |

| 6.4ZPC001 | ZnSe | 16.2mm | 2.7mm | AR/17% |

| 6.4ZPC0020 | ZnSe | 16.2mm | 2.7mm | AR/17% |

| 10GER15-99 | Ge | 25.4mm | 6mm | AR/99.6% |

| 10GER20-99 | Ge | 25,4mm | 3mm | AR/99.5% |

| 10ZPC0010 | ZnSe | 25.4mm | 3mm | AR/40% |

| 10ZPC0015 | ZnSe | 25.4mm | 3mm | AR/50% |

| 10ZPC0020 | ZnSe | 25.4mm | 3mm | AR/50% |

| 10ZPC0022 | ZnSe | 25.4mm | 6mm | AR/50% |

| 10ZPC0030 | ZnSe | 25.4mm | 3mm | AR/50% |

| 10ZPC0040 | ZnSe | 25.4mm | 6mm | AR/50% |

| 10ZPC0024 | ZnSe | 25.4mm | 3mm | AR/85% |

| 10ZPC0050 | ZnSe | 25.4mm | 6mm | AR/55% |

| 10ZPC0060 | ZnSe | 25.4mm | 6mm | AR/65% |

| 10ZPC0062 | ZnSe | 25.4mm | 3mm | AR/99.5% |

| 10ZPC0063 | ZnSe | 25.4mm | 3mm | AR/99.5% |

| 10ZPC0064 | ZnSe | 25.4mm | 3mm | AR/99.5% |

| 10ZPC0066 | ZnSe | 25.4mm | 4.7mm | AR/99% |

| 10ZPC0068 | ZnSe | 25.4mm | 4mm | AR/60% |

| 10ZPC0070 | ZnSe | 25.4mm | 6mm | AR/99.6% |

| 10ZPC0080 | ZnSe | 25.4mm | 6mm | AR/99.6% |

| 10ZPC0085 | ZnSe | 25.4mm | 6mm | AR/99.6% |

| 10ZPC0090 | ZnSe | 25.4mm | 6mm | AR/99.6% |

| 11GER10-99.5 | Ge | 28mm | 6mm | AR/99.5% |

| 11GER20-99.5 | Ge | 28mm | 6mm | AR/99.5% |

| 11GER30-99.5 | Ge | 28mm | 5.6mm | AR/99.5% |

| Part No | Material | Diameter | ET | Coating |

| 11MNFO010 | ZnSe | 28mm | 4mm | AR/50% |

| 11MNFO020 | ZnSe | 28mm | 4mm | AR/50% |

| 11MNFO030 | ZnSe | 28mm | 4mm | AR/50% |

| 11MNFO040 | ZnSe | 28mm | 4mm | AR/75% |

| 11MNRO10 | ZnSe | 28mm | 4mm | AR/99.2% |

| 11MNRO020 | ZnSe | 28mm | 4mm | AR/99.2% |

| 11NFO010 | ZnSe | 28mm | 4mm | AR/50% |

| 11NFO020 | ZnSe | 28mm | 3mm | AR/50% |

| 11NFO030 | ZnSe | 28mm | 6mm | AR/50% |

| 11NFO040 | ZnSe | 28mm | 3mm | AR/75% |

| 11NRO010 | ZnSe | 28mm | 4mm | AR/99.2% |

| 11NRO020 | ZnSe | 28mm | 4mm | AR/99.2% |

| 11ZPC0010 | ZnSe | 28mm | 6mm | AR/50% |

| 11ZPC0016 | ZnSe | 28mm | 6mm | AR/17% |

| 11ZPC0017 | ZnSe | 28mm | 6mm | AR/17% |

| 11ZPC0018 | ZnSe | 25.4mm | 6mm | AR/17% |

| 11ZPC0020 | ZnSe | 25.4mm | 6mm | AR/60% |

| 11ZPC0022 | ZnSe | 28mm | 6mm | AR/60% |

| 11ZPC0030 | ZnSe | 28mm | 6mm | AR/65% |

| 11ZPC0033 | ZnSe | 28mm | 3mm | AR/99% |

| 11ZPC0040 | ZnSe | 28mm | 4mm | AR/65% |

| 11ZPC0041 | ZnSe | 28mm | 4mm | AR/40% |

| 11ZPC0049 | ZnSe | 28mm | 4mm | AR/40% |

| 11ZPC0050 | ZnSe | 28mm | 6mm | AR/99% |

| 11ZPC0059 | Ge | 28mm | 6mm | AR/50% |

| 12.6ZPC0010 | Ge | 32mm | 5mm | AR/99.6% |

| Part No | Material | Diameter | ET | Coating |

| 15GER35-99.5 | Ge | 38.05mm | 4mm | AR/99.5% |

| 15ZPC0016 | ZnSe | 38.05mm | 6.3mm | AR/99.6% |

| 15ZPC0020 | ZnSe | 38.05mm | 6mm | AR/99.6% |

| 15ZPC0060 | ZnSe | 38.05mm | 8mm | AR/60% |

| 15ZPC0097 | ZnSe | 38.05mm | 6.18mm | AR/97% |

| 20ZPC0011 | ZnSe | 50.8mm | 5mm | AR/85% |

Flat Partial Reflectors

he following flat partial reflectors are available. Other are available upon request.

| Part No | Material | Diameter | ET | Coating |

| 10ZPF3-17-N | ZnSe | 25.4mm | 3mm | AR/17% |

| 10ZPF3-40-N | ZnSe | 25.4mm | 3mm | AR/40% |

| 10ZPF3-50-N | ZnSe | 25.4mm | 3mm | AR/50% |

| 10ZPF3-60-N | ZnSe | 25.4mm | 3mm | AR/60% |

| 10ZPF3-65-N | ZnSe | 25.4mm | 3mm | AR/65% |

| 10ZPF3-70-N | ZnSe | 25.4mm | 3mm | AR/70% |

| 10ZPF3-75-N | ZnSe | 25.4mm | 3mm | AR/75% |

| 10ZPF3-80-N | ZnSe | 25.4mm | 3mm | AR/80% |

| 10ZPF3-85-N | ZnSe | 25.4mm | 3mm | AR/85% |

| 10ZPF3-85-S | ZnSe | 25.4mm | 3mm | AR85%-45S |

| 10ZPF3-90-N | ZnSe | 25.4mm | 3mm1 | AR/90% |

| 10ZPF3-95-N | ZnSe | 25.4mm | 3mm | AR/95% |

| 10ZPF3-99-N | ZnSe | 25.4mm | 3mm | AR/99% |

| 10ZPF3-99-R | ZnSe | 25.4mm | 3mm | AR/99%-45S |

| 10ZPF4-85-N | ZnSe | 25.4mm | 4mm | AR/85% |

| 10ZPF6-50-N | ZnSe | 25.4mm | 6mm | AR50% |

| 10ZPF6-60-N | ZnSe | 25.4mm | 6mm | AR/60% |

| 10ZPF6-65-N | ZnSe | 25.4mm | 6mm | AR/65% |

| 11GPF8679 | GaAs | 28mm | 3mm | AR/65% |

| 11ZPF3-27-N | ZnSe | 28mm | 3.1mm | AR/27% |

| 11ZPF3-50-N | ZnSe | 28mm | 3mm | AR/50% |

| 11ZPF3-60-N | ZnSe | 28mm | 3mm | AR/60% |

| 11ZPF3-65-N | ZnSe | 28mm | 3.1mm | AR/65% |

| 11ZPF3-85-N | ZnSe | 28mm | 3.1mm | AR/85% |

| 11ZPF6-60-N | ZnSe | 28mm | 6mm | AR/60% |

| 12.6ZPF5-17-N | ZnSe | 32mm | 5mm | AR/17% |

| Part No | Material | Diameter | ET | Coating |

| 15ZPF3-17-N | ZnSe | 38.05mm | 3mm | AR/17% |

| 15ZPF3-1-N | ZnSe | 38.05mm | 3mm | AR/1% |

| 15ZPF3-25-N | ZnSe | 38.05mm | 3mm | AR/25% |

| 15ZPF3-28-S | ZnSe | 38.05mm | 3mm | AR/28%-45S |

| 15ZPF3-33-N | ZnSe | 38.05mm | 3mm | AR/33.3% |

| 15ZPF3-45-R | ZnSe | 38.05mm | 3mm | AR/45-45R |

| 15ZPF3-50-N | ZnSe | 38.05mm | 3mm | AR/50% |

| 15ZPF3-57-N | ZnSe | 38.05mm | 3mm | AR/57% |

| 15ZPF3-5-S | ZnSe | 38.05mm | 3mm | AR/5%-45S |

| 15ZPF3-60-N | ZnSe | 38.05mm | 3mm | AR/60% |

| 15ZPF3-65-N | ZnSe | 38.05mm | 3mm | AR/65% |

| 15ZPF3-70-N | ZnSe | 38.05mm | 3mm | AR/70% |

| 15ZPF3-75-N | ZnSe | 38.05mm | 3mm | AR/75% |

| 15ZPF3-80-N | ZnSe | 38.05mm | 3mm | AR/80% |

| 15ZPF3-85-N | ZnSe | 38.05mm | 3mm | AR/85% |

| 15ZPF3-90-N | ZnSe | 38.05mm | 6mm | AR/90% |

| 15ZPF4-25-N | ZnSe | 38.05mm | 4mm | AR/25% |

| 15ZPF4-60-N | Znse | 38.05mm | 4mm | AR/60% |

| 15ZPF6-99-N | ZnSe | 38.05mm | 6mm | AR/99% |

| 15.7ZPF4-50N | ZnSe | 40mm | 4mm | AR/50% |

| 17.5ZPF4-17-N | ZnSe | 44.45mm | 4mm | AR/17% |

| 19.7ZPF4-50N | ZnSe | 50mm | 4mm | AR/50% |

| 20ZPF5-99-P9.4 | ZnSe | 50.08mm | 5mm | AR/50%-45S |

| 20ZPF5-99-s-9.4 | ZnSe | 50.08 | 5mm | AR/50%-45P |

Beam Combiners

ULO Optics’ beam combiners allow coupling a low power visible red laser into a beam path of a high power infrared beam for set-up of the downstream optics. They transmit the high power CO2 beam, and reflect the aiming laser at 45 degrees, overlapping the two beams. Standard components are available for 10.6 μm / 633 or 670 nm. Other wavelength combinations are possible, but note that the ‘reverse beam combiner’ where the long wavelength is reflected and the short wavelength transmitted are not possible. It is possible to simulate the latter by using a normal beam combiner with additional mirrors.

The beam combiners are supplied mounted with a red diode laser in our CO2mpact unit C-BI

- R at 633 or 670nm > 99% at 45 degrees

- T at 10.6 μm > 99%

Total Reflectors

ULO Optics manufactures Silicon and Copper mirrors and phase retarders, with different configurations specifically designed for high and low power lasers.

For more information:

- Mirrors

- Phase Retarders

Dimensional tolerances for standard lenses, windows and mirrors are as follows:

- Diameter: +0/-0.1 mm for most diameters, +0/-0.05 mm for 1.5″ lenses

- Centre thickness: +/-0.1 mm

- Edge thickness variation: most lenses within 0.03 mm and some within 0.05 mm

- Focal length: +/-0.5%. Some long focal singlet scanning lenses can be 1 to 2% due to highly meniscus shape

- Surface form: typically less than 1 visible fringe on a 38 mm diameter test area

- Surface roughness: within 20 Å rms

Tighter tolerances are possible on custom optics. Sometimes they are interrelated if very tight, e.g. the achievable flatness on a window can depend on the thickness (rigidity).

Silicon & Copper Mirrors

ULO Optics offer silicon and copper mirrors with various diameters and thicknesses. Our silicon mirrors are extremely durable, and combined with our Supermax coating offer reflectivity greater than 99.85%. Copper mirrors, most suitable to higher power lasers are also Supermax coated to guarantee the same reflectivity. Another version of a Copper mirror is coated with Gold, offering a more economical alternative where 99% reflectivity is sufficient. These are commonly refered to as ‘NiCu’ type mirrors, due to a layer of Nickel underneath the Gold coating.

- Gold (on copper mirrors) or Supermax coating

- Air and water-cooled versions of copper mirrors

Phase Retarding Mirrors

Used to convert beams with linear polarization into circular polarization, ULO Optic’s phase retarders are mainly used in metal cutting systems to ensure consistent cut quality in all cutting directions.

ULO Optics manufactures both silicon and copper phase retarders. Silicon phase retarders are available in both ?/8 and ?/4 types (45° and 90° retardation). Copper phase retarders are available as ?/4 type only. They have a higher laser damage threshold than silicon phaser retarders.

- 90 degree +/- 3degrees (< 1 degree possible on request) phase retardation

- Typical reflectance > 98.5%

- Substrates up to 5“ diameter available

- available mounted in our mirror blocks