ULO delivers optical engineering and manufacturing solutions for industry, aerospace, defence and life sciences. Our expertise enables our customers to innovate and excel in their respective fields.

With over four decades’ experience designing and fabricating precision optics, ULO has a distinguished track record. Our engineers have developed optics that have become industry standards and have collaborated with OEM customers to tailor the highest quality custom components.

Discover Precision: Explore our industry-leading Optics solutions.

Discover our range of standard and custom designed laser mirrors wth ultra-smooth polished surfaces

As the leading European manufacturer of infrared optics, ULO supplies a full range of optics for CO2 laser manufacturers and CO2 laser users.

We manufacture a wide range of Beam Delivery systems for industrial applications. We are leading the drive to make sophisticated beam delivery equipment more affordable without compromising quality.

As part of our manufacturing process for polished and coated finished optics, we are able to offer generated blanks with tight tolerances for thermal imaging applications.

ULO Optics is an ISO certified company and quality is at the heart of everything we do. With a host of industrial affiliations, you can rely on ULO to deliver.

Industrial lasers have revolutionized manufacturing processes across various industries, offering unparalleled precision, efficiency, and versatility.

Our beam delivery components have long been employed by the medical industry, most notably in Fractional Laser Skin Resurfacing (Frax 1550) and dental laser applications.

Our Generated Blanks offer superior resistance to high-speed dust abrasion and rain erosion, making them especially suited to external IR window applications.

Our team offers unparalleled technical expertise to aid in the development of innovative products and actively participates in industry projects aimed at advancing various sectors.

Working alongside Centro Ricerche FIAT, we developed the optics for the Modulase processing head used for cutting, cladding and welding applications in the automotive industry.

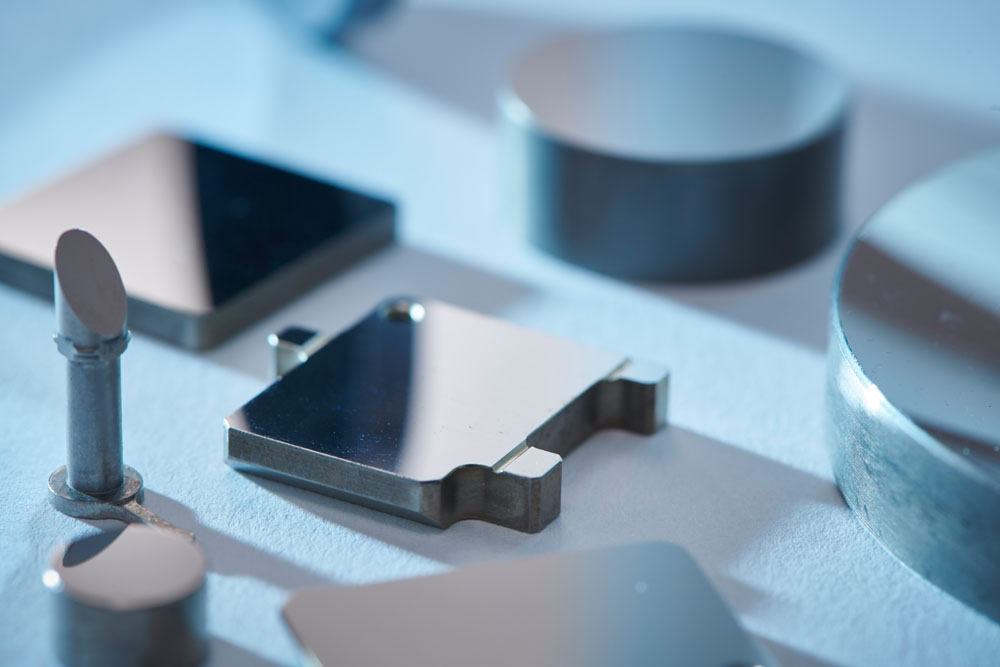

We can produce technically advanced shapes with extreme precision including elipses, toroids, spheres, polygons, pyramids, infrared domes and many more

We offer aluminium mirrors for scanning systems between 1 and 11 microns.

We manufacture, repair and stock a complete range of high quality mirrors for CO2 laser welding, cutting and engraving systems.

Er:YAG are solid state lasers operating at 2.94 microns wavelength. This wavelength of light is strongly absorbed by water, so Er:YAG lasers are popular in dentistry and surgery.

Our metal mirrors are used for many applications in the near infrared typically 800nm to 5μm wavelength.

Our gold coated mirrors offer a broad and consistent reflectivity in the infrared spectrum from 800nm to the far infrared beyond 300um wavelength.

Hard gold coated mirrors for high power Fibre Laser applications.