Projects

Collaborative Projects: Advancing Innovation Together

As a leading provider of optical solutions, ULO Optics actively participates in a wide array of projects across different industries and sectors. Our involvement in these projects stems from our commitment to innovation, collaboration, and problem-solving. By engaging in diverse initiatives, we strive to leverage our expertise, technologies, and resources to address complex challenges, drive advancements, and contribute to the success of our partners and clients. At ULO Optics, we believe that collaboration and shared knowledge are essential drivers of progress, and we are dedicated to playing a pivotal role in shaping the future through our participation in various projects.

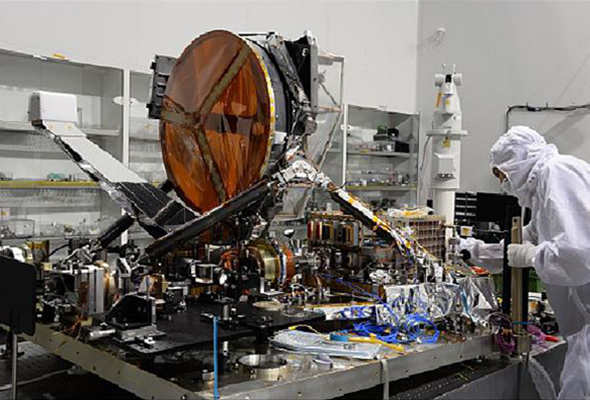

ESA Living Planet Multi-Spectral Imager Instrument

ULO Optics contributed the polished Zinc Selenide optics for this instrument, which is part of a European-Japanese mission, addressing the need for a better understanding of the interactions between cloud, radiative and aerosol processes that play a role in climate regulation.

One of the lenses manufactured for the instrument is shown in the picture above. The optics also included lenses and windows for the TIR camera.

Read more about this project at the European Space Agency

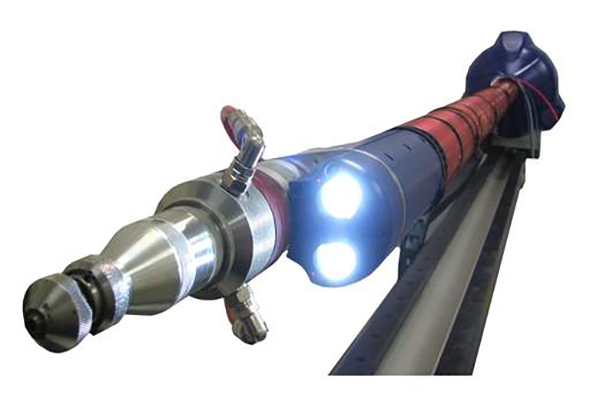

Laser Snake II - Nuclear Decommisioning

ULO Optics collaborated with OC Robotics and TWI Ltd as part of a UK Technology Strategy Board competition for nuclear R&D feasibility studies.

For this study a snake-arm robot was combined with a 5kW laser to enable a selective, remote-controlled approach to dismantling and decommissioning complex structures in hazardous and confined nuclear environments.

Read more about this project at bbc.co.uk

Modulase

ULO Collaborate with partners including Centro Ricerche Fiat, TWI and EWF on the Modulase project. ModuLase aims to develop, validate & demonstrate a rapidly re-configurable laser process head that:

- Is capable of welding, cladding and cutting, through the use of three modular end-effectors

- Includes intelligent sensor technologies for in-process monitoring

- Is linked to an intelligent system, in order to achieve adaptive process control, quality assurance, and semi-automated process parameter configuration.

This will be achieved through the use of a Beam Forming Unit (BFU) and modular end-effectors (akin to changing a computer numerical control (CNC) machining tool).

Read more about the modulase project at Modulase.eu

Project partners

Through collaboration with a number of industry-leading partners, ULO seek to advance engineering in specialist areas across a range of industry sectors. Our contributions to these projects allow us to train and up-skill the next generation of optical experts.