Industrial

Industrial Lasers

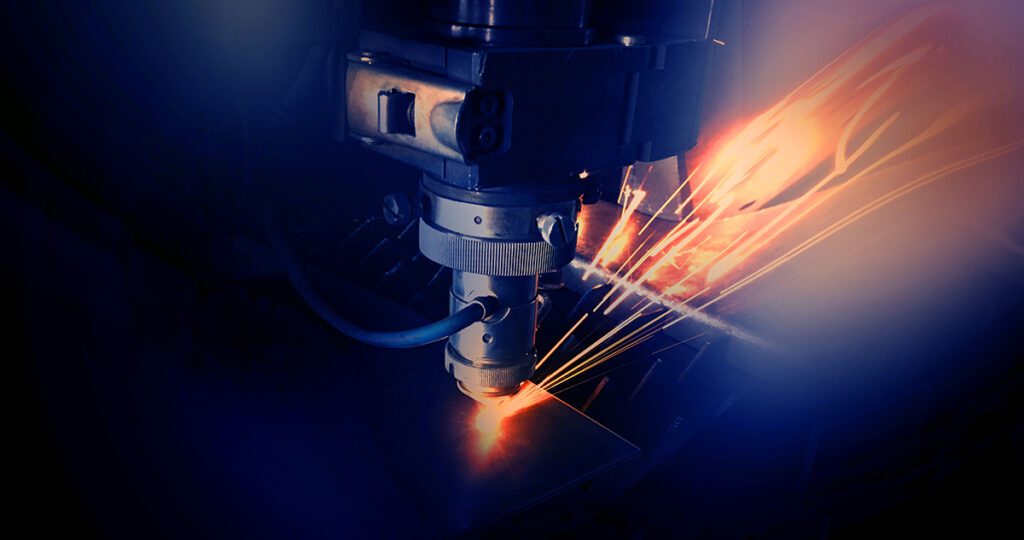

Industrial lasers have revolutionized manufacturing processes across various industries, offering unparalleled precision, efficiency, and versatility. These powerful tools harness the focused energy of light to perform a wide range of tasks, from cutting and welding to marking and engraving.

One of the primary applications of industrial lasers is in material processing, where they are used for cutting, welding, and surface treatment across a wide range of materials, including metals, plastics, ceramics, and composites. Laser cutting, for example, offers high-speed, high-precision cutting with minimal heat-affected zones, making it suitable for intricate designs and delicate materials.

ULO Optics manufactures a variety of lenses, reflectors, and windows, catering to both OEMs and end users seeking replacement parts. Additionally, we supply OEM-style protection windows, collimators, and beam expanders tailored for 1µm fiber laser systems.

ZnSe Generated Blanks

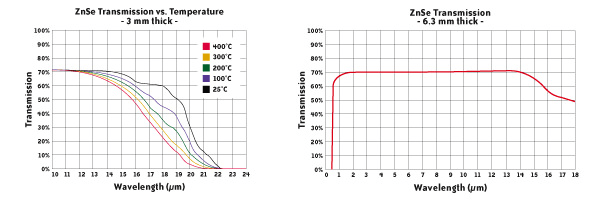

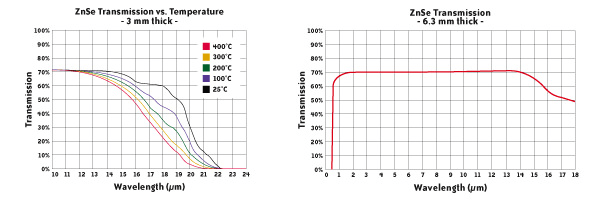

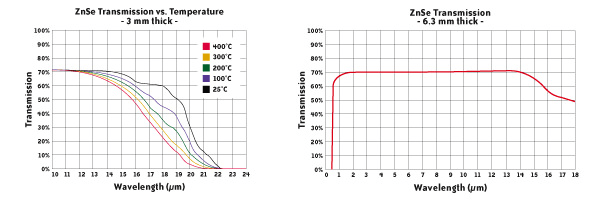

As an integral part of our manufacturing process for polished and coated finished optics, we proudly offer generated blanks with precise tolerances tailored for thermal imaging applications. The primary materials utilized in the majority of our lenses, spanning various applications, are ZnSe and ZnS. These lenses are meticulously crafted to meet the highest industry standards, underpinned by state-of-the-art metrology techniques.

With our advanced manufacturing capabilities, we can accommodate diameters ranging from 15mm to 150mm, ensuring versatility and flexibility to meet diverse customer needs. Whether for thermal imaging or other optical applications, you can rely on ULO Optics to deliver precision-engineered optics of the utmost quality and reliability.

Zinc Sulfide Generated Blanks

Our Zinc Sulphide is cultivated through a meticulous chemical vapor deposition process, resulting in a material renowned for its exceptional hardness and fracture strength. This remarkable durability makes Zinc Sulphide an ideal choice for applications in harsh environments and military settings.

Notably, Zinc Sulphide’s resistance to high-speed dust abrasion and rain erosion further enhances its suitability for external infrared (IR) windows on aircraft. These windows play a critical role in maintaining visibility and functionality in challenging conditions, ensuring optimal performance even in adverse weather conditions.

At ULO Optics, we take pride in offering Zinc Sulphide solutions that exceed industry standards, providing reliability and durability in the most demanding environments. Whether for military applications or other high-stakes scenarios, our Zinc Sulphide products deliver unmatched performance and peace of mind.

MultiSpectral Zinc Sulfide

Multispectral Zinc Sulfide undergoes a meticulous hot isostatic press treatment process, designed to eliminate any defects present within its crystalline lattice. This specialized treatment ensures the material’s integrity and enhances its optical properties.

Known for its exceptional performance across a broad spectrum of wavelengths, spanning from 0.4 to 12 microns, multispectral Zinc Sulfide stands out for its remarkable attributes. With high transmission capabilities and minimal scatter, it offers unparalleled clarity and efficiency in various optical applications.

ULO Optics offers multispectral Zinc Sulfide customized to exacting specifications, ensuring that each product meets the stringent requirements of our customers. From precision optics to cutting-edge technologies, our commitment to delivering excellence remains unwavering, making us the trusted choice for all your optical needs.

Unlocking Precision with Laser Technology

Our optics find applications globally in processes like flatbed sheet metal cutting, laser scanning, and marking. In laser marking, we cater to diverse sectors such as textile marking in the fashion industry and coding for traceability, including food packaging where batch numbers and use-by dates are crucially applied to various materials, including food products themselves.

For precision and durability, laser marking is extensively employed in producing ID cards such as passports and driving licenses, serving anti-counterfeiting purposes effectively.

ULO Optics boasts an extensive range of stock items and a rich history of delivering high-quality bespoke solutions to the industrial laser market.

Types:

CO2 Lasers: Emitting infrared light, CO2 lasers are widely used for cutting, engraving, and welding materials like wood, plastics, fabrics, and metals.

Fiber Lasers: Utilizing optical fibers as the gain medium, fiber lasers offer high power, efficiency, and precision, making them ideal for metal cutting, marking, and microprocessing applications.

Nd:YAG Lasers: Operating at various wavelengths, Nd:YAG lasers find applications in welding, drilling, and surface treatment of metals and ceramics.

Excimer Lasers: Emitting short-wavelength ultraviolet light, excimer lasers are used in semiconductor manufacturing, photolithography, and medical procedures like LASIK eye surgery.

Diode Lasers: Diode lasers are compact, efficient, and versatile, finding applications in material processing, medical procedures, telecommunications, and research.

Applications:

Material Processing: Laser cutting, welding, drilling, and surface treatment are common applications in industries such as automotive, aerospace, electronics, and construction.

Marking and Engraving: Laser marking provides permanent, high-resolution labeling for product identification, branding, serialization, and traceability across various materials.

Additive Manufacturing: Laser-based 3D printing technologies, such as selective laser melting (SLM) and stereolithography (SLA), enable rapid prototyping and production of complex geometries in industries like aerospace, healthcare, and automotive.

Microelectronics: Laser micromachining, lithography, and annealing processes are essential in semiconductor fabrication, PCB manufacturing, and microelectronics assembly.

Medical and Biotechnology: Laser systems are utilized in medical diagnostics, surgery, dermatology, ophthalmology, and biophotonics for procedures like tissue ablation, imaging, and therapy.

Research and Development: Industrial lasers play a crucial role in scientific research, spectroscopy, metrology, and optical communications, driving innovation and discovery in various fields.

Significance:

Precision and Accuracy: Industrial lasers offer unmatched precision, enabling micron-level accuracy and repeatability in manufacturing processes.

Versatility and Flexibility: With customizable parameters and beam characteristics, lasers adapt to diverse materials, shapes, and applications, enhancing process flexibility and efficiency.

Automation and Integration: Integrated with robotic systems and CNC machinery, industrial lasers facilitate automated, lights-out manufacturing, optimizing production throughput and reducing labor costs.

Quality and Consistency: Laser-based processes ensure high-quality, uniform results, minimizing defects, material waste, and rework in industrial production.

As technology continues to evolve, the role of lasers in shaping the future of industrial processes and product development remains pivotal, promising continued advancements and breakthroughs in various domains.

Industrial Laser Optics

Laser optics are integral to a multitude of laser-based instruments and applications, such as directing beams or processing materials. They are engineered with particular substrates and coatings, or their combination, to excel in performance across specific or a spectrum of laser wavelengths. Optics for lasers often come with designated laser damage thresholds, suitable for either pulsed or continuous wave (CW) lasers. It’s crucial to match the laser optic to the laser’s requirements, as using one with a lower damage threshold can result in damage to the component.

ULO Optics manufactures an extensive selection of Laser Optics, including lenses, mirrors, filters, and other laser-compatible components. Laser Lenses are crafted to focus, even out, or sculpt laser beams. Laser Mirrors are perfect for applications that involve steering beams. Laser. Laser Windows serve the dual purpose of transmitting specific wavelengths and shielding sensitive areas or components from errant light.

Distinct from general optical components, laser optics are tailored for laser applications. While general optics might be made from standard glass types with broad-spectrum coatings or no coating to suit various wavelengths, laser optics are specialized. They utilize unique materials in their construction and coatings to optimize performance for the laser’s specific operational wavelengths. Additionally, for applications involving high-power or ultrafast lasers, which are highly specialized, the laser optics must meet stringent tolerances for factors such as absorption, dispersion, thermal conductivity, laser-induced damage thresholds (LIDT), surface quality, coating properties, and more.