PROTECTION Windows

Fiber Laser Protection Windows

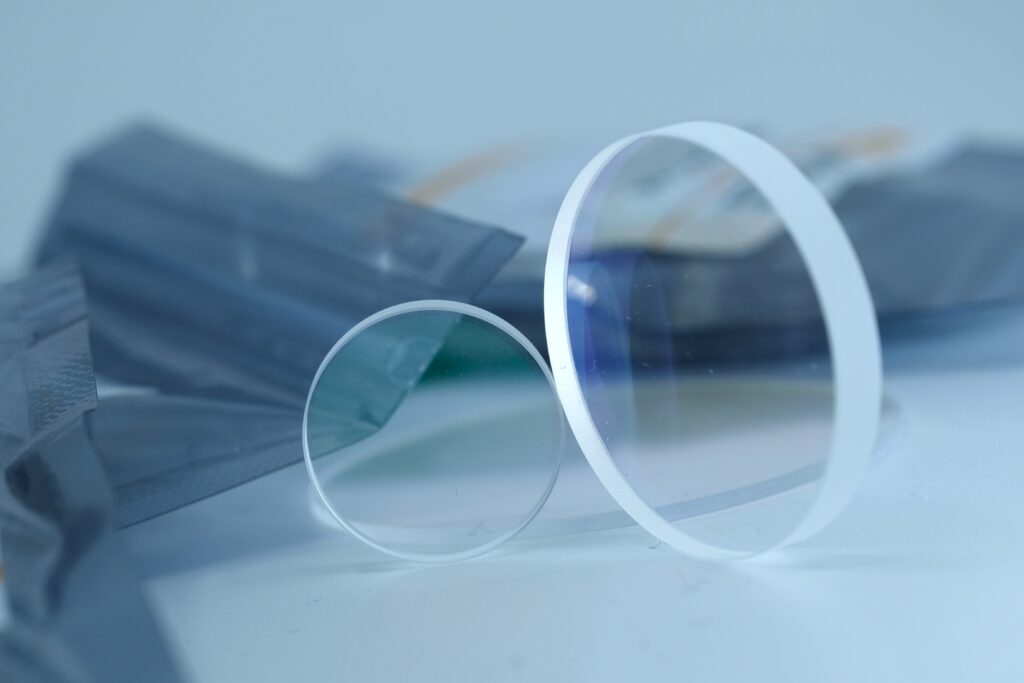

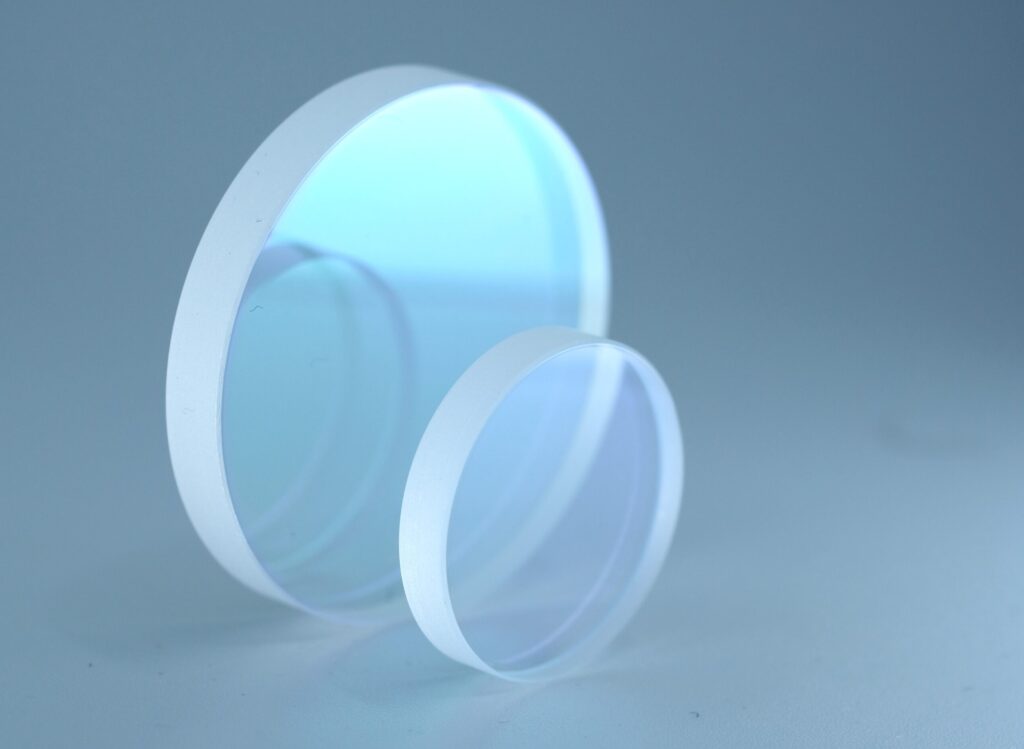

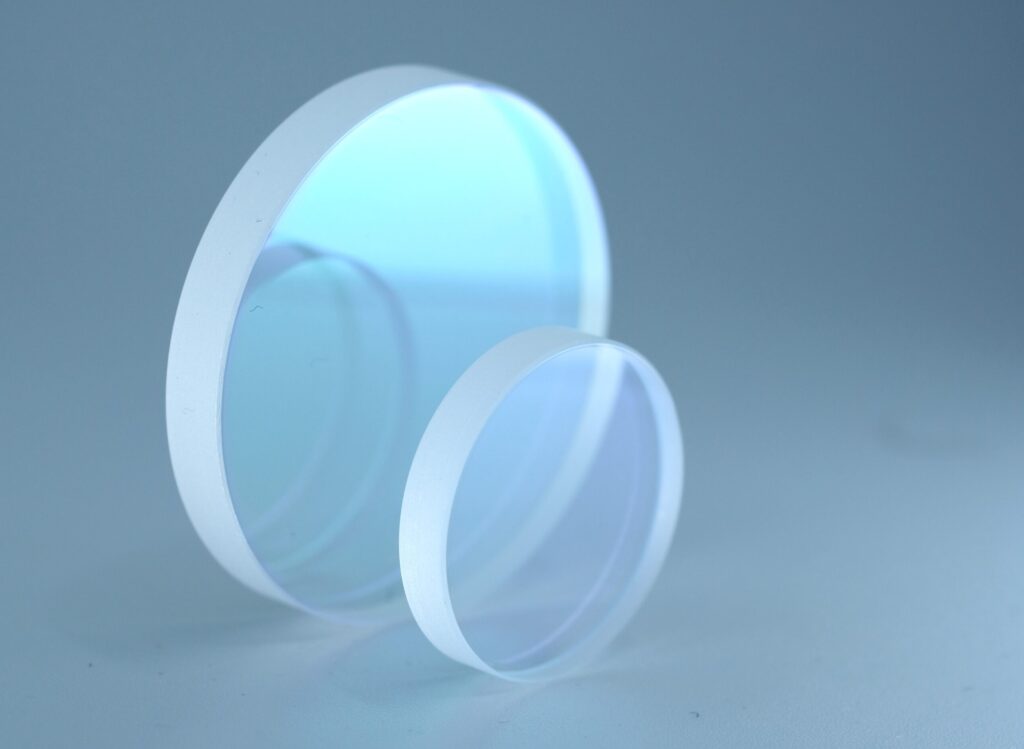

ULO Optics’ Fiber Laser Protection windows serve a vital role in safeguarding your system from back spatter, smoke residue, and steam, while also serving as a pressure window for the cutting gas. These protective windows, also referred to as cover slides or debris shields, are available in a variety of shapes and sizes to suit different applications.

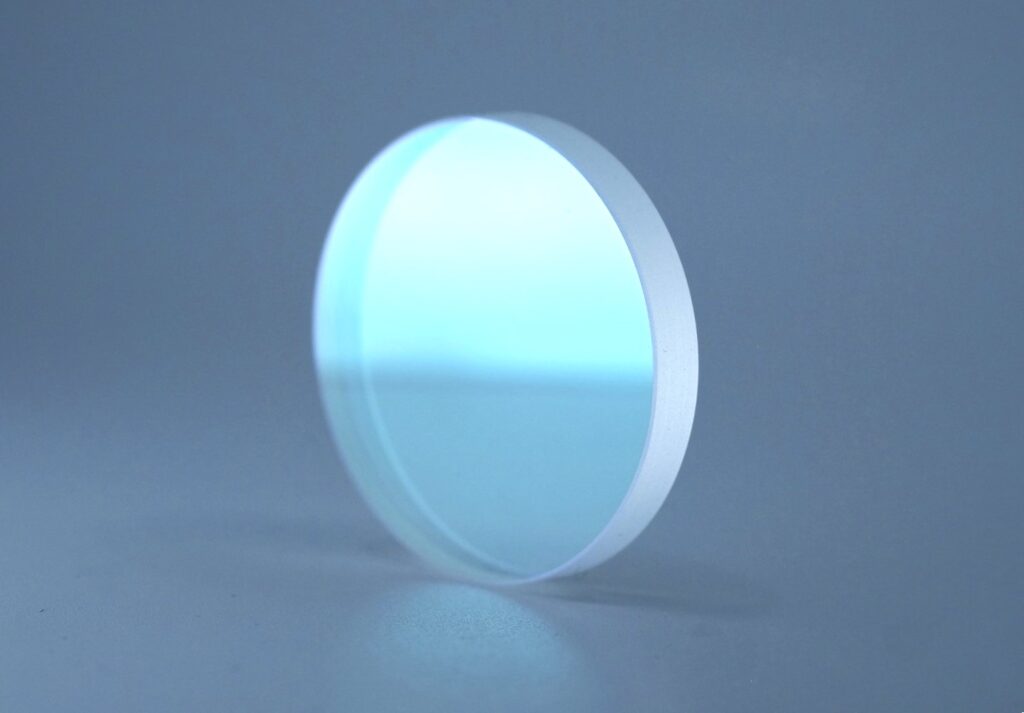

Positioned as the final optical element between the focusing lens and the working area, our protection windows are instrumental in shielding other, more costly optical elements in your fiber or YAG laser setup. To ensure optimal performance and longevity, all our protection windows are equipped with anti-reflective (AR) coatings. These coatings minimize absorption and mitigate damage caused by back reflection or thermal changes to the glass.

At ULO Optics, we offer AR coatings tailored to the wavelength range of 200-3000nm, with options including Narrow-band, Broadband, and Multispectral coatings. Additionally, our protective windows are available in various substrates, with popular options including Fused Silica, BK7, Borosilicate glass 3.3, Float glass, and Sapphire. With our comprehensive range of options, you can trust ULO Optics to provide the ideal protection windows to suit your specific requirements and applications.

With our laser protection windows, you can trust that your fiber laser system is equipped with the highest level of safety and performance. Backed by our expertise and commitment to excellence.

Experience the Difference Today!

Upgrade your fiber laser system with our premium laser protection windows and experience enhanced safety, efficiency, and peace of mind. Explore our range of products and discover why ULO Optics is the trusted choice for laser safety solutions in industrial settings.

Key Advantages:

- Low absorption and high transmission.

- Anti-reflective (AR) coatings for enhanced performance.

- Premium Material Composition: Made from high-quality materials including fused silica, sapphire, and specialized optical-grade glasses, our windows offer exceptional optical transmission properties at the laser wavelength. Not only do they provide superior protection, but they also exhibit high resistance to thermal damage, ensuring longevity and durability in demanding industrial environments.

- Available in several diameters, shapes, and sizes.

- Custom design and fabrication available upon request.

- Easy Installation and Maintenance: Designed for hassle-free installation and replacement, our windows minimize downtime and maintenance costs for your fiber laser system, keeping your operations running smoothly and efficiently.

- Robust Construction: Our windows are built to withstand the rigors of industrial operations, withstanding intense energy and thermal fluctuations generated by fiber laser systems. Rigorous testing and quality assurance measures guarantee that our products deliver reliable performance under the most challenging conditions.

ULO Optics offers standard laser protection windows with the following specifications:

- Substrate: Fused Silica, ideal for high-power lasers.

- Tolerance: Diameter ±0.1mm or +0/-2.0mm, Thickness ±0.1mm or +0/-0.2mm.

- Edges grinded with a facette (e.g., 0.3mm x 45°).

- Both sides mechanically polished to λ/4-λ/6.

- Scratch/dig specifications: 60/40 or 40/20.

- Typical Standard Coatings:

- @1064nm: Transmission ≥99.6%.

- @633nm: Transmission ≥95%.

- Or broad band coating: e.g., @900-1080nm: Transmission ≥99.5%.

- Smudge and scratch-resistant, adhesive peeling tested.

- Ultrasonically cleaned in a dust-free booth.

Common Proctection Windows

The following standard protection windows are currently available. Others may be available upon request.

| Part No | Material | Diameter | ET | Coating |

| 19.7FSW3-00 | FS | 19.7mm | 3mm | AR/AR |

| 22.35FSW5-00 | FS | 22.35mm | 4mm | AR/AR |

| 24FSW4-00 | FS | 24mm | 5mm | AR/AR |

| 27.9FSW4.1-00 | FS | 27.9mm | 4.1mm | AR/AR |

| 30FSW1.5-00 | FS | 30mm | 1.5mm | AR/AR |

| 30FSW5-00 | FS | 30mm | 5mm | AR/AR |

| 34FSW5-00 | FS | 34mm | 5mm | AR/AR |

| Part No | Material | Diameter | ET | Coating |

| 34FSW5-00 | FS | 34mm | 5mm | AR/AR |

| 35FSW1.5-00 | FS | 35mm | 1.5mm | AR/AR |

| 36FSW5-00 | FS | 36mm | 5mm | AR/AR |

| 37FSW7-00 | FS | 37mm | 7mm | AR/AR |

| 40FSW7-00 | FS | 40mm | 7mm | AR/AR |

| 50FSW8-00 | FS | 50mm | 8mm | AR/AR |

| 55FSW1.5-00 | FS | 55mm | 1.5mm | AR/AR |